Everything You Need To Know About Inventory Control

Controlling and managing your inventory is a crucial part of keeping your business afloat by preventing overselling, stock shortages and enabling correct record keeping. This guide will discuss several ways to help you oversee your inventory and the benefits of using a modern inventory control system as opposed to manually logging and inputting stock.

What is inventory control?

Inventory control (also known as stock control) is the process of keeping on top of inventory levels across an entire business and across the entire lifecycle of that inventory (from receiving from suppliers to shipping to customers). A good inventory control system helps avoid shortages, overstocks, and other costly problems within the warehouse.

Companies that use effective inventory control systems will be able to reduce the number of slow-selling products they have on the shelves while increasing the number of high-selling products.

This is a highly cost-effective and time-efficient way to control the goods in your business by eliminating items that do not contribute to the success of finances, whilst freeing up warehouse space for the sale of additional items. The effective use of inventory control prevents any room for errors with your financial expenses, it stops overspending on unpopular items, and maintains inventory levels.

What are the different methods of inventory control?

There are multiple ways to control your inventory; it’s important to decide what method is best for you and your business. Often the method you choose will be determined by the size of your business right now and/or your ambitions for future growth.

Manual inventory control methods

There are some manual methods, like the old-fashioned use of pen and paper and excel spreadsheets, that can help control your inventory. These are more suited to smaller businesses that have the time and ability to manually log items.

As soon as you start selling across more than one channel, manual inventory control processes are likely to break down. This is because, unless you have someone capable of tracking inventory in real-time, you are likely to oversell.

Pen and paper

Using a pen and paper is an inexpensive way to log your inventory. However, using pen and paper has the potential to get very messy very quickly, and should probably be avoided.

Spreadsheets

Another manual method is the use of an Excel or Google spreadsheet to store information. However, the spreadsheet cannot be automatically updated. Ideally, to use this method, a business should rely on an employee that knows the inventory inside and out to update it.

Both methods are time-consuming ways to log your inventory and leave a lot of room for human error and mistakes.

Stock cards

A stock card is a document that helps track inventory by processing purchases, sales, returns, unit prices, and so on. It can be used to display how much stock exists at any one time and contains a wide range of information, including description, value, supplier details, quantities, and lead times, as well as additional information regarding past stock history.

Stock cards are great for beginners and can be filed for easy access; however, they can risk being damaged or lost.

Basic Inventory Management Software

Basic software solutions will likely help users keep information in one place and have limited available automations. They are more suitable for hobby businesses or businesses without serious plans for growth. This is because it may lack the features needed for more complex multichannel ecommerce.

Advanced Management Software

Advanced management software comes with impressive reporting features and the ability to sync with multiple channels. It should integrate with all other ecommerce tools retailers need and help manage warehouse and shipping operations.

This software can adapt and develop with the growing needs of a business.

Learn more about Veeqo’s advanced inventory management software.

Periodic vs perpetual inventory systems

When researching the best inventory control method for you, you are likely to come across the terms ‘periodic’ or ‘perpetual inventory’.

Periodic

A periodic inventory system is catered more towards smaller businesses yet can be used by a business of any size. It employs regular physical counts of the stock to calculate the level of inventory and the costs of goods sold (COGS). At the end of a set period, the inventory and cost of goods sold are updated manually.

Perpetual

A perpetual inventory system keeps track of inventory balances on a continual basis, with updates automatically generating as soon as products are received or sold. Perpetual systems are necessary for any eCommerce retailer looking to take advantage of multichannel ecommerce or that has more complex fulfillment needs.

Updates are automatic as soon as goods are received or sold and the COGS are also updated straight away. As for sales, they are immediately recorded in an inventory live count. Meaning that the live count should always be correct if there is no theft in-store or damage.

You can learn more about perpetual inventory systems in this guide.

Elements of a modern inventory control system

When looking for an inventory control solution for multichannel ecommerce, it’s important to know what to look for. While solutions may have more features than those listed below, these are some of the more important ones you will need to have complete control over your stock.

Syncing across multiple channels

It is important to have an inventory control system that can sync across multiple channels. Veeqo, for example, syncs inventory across 17+ different sales channels, including Amazon integration, eBay, and much more.

Inventory tracking across multiple locations

As mentioned earlier, a modern inventory control system tracks inventory across multiple locations (such as warehouse, FBA and retail store) and ensures that accurate stock levels are always available for your team, saving your workers time and energy.

Real-time syncing

A modern perpetual inventory control system, like Veeqo, will sync your inventory in near to real-time. Meaning that if you make a sale anywhere it is recorded everywhere, immediately. This gives you a live inventory count.

Connecting with shipping carriers

A true inventory control solution will also connect with shipping carriers, giving you complete visibility of where your inventory is right up to the end of its journey.

Tracking returns

This is important to ensure any items returned by the customer safely arrive back to your warehouse. It’s also imperative that you are able to get reports on your returns as you can use that data to make relevant business decisions relating to products and processes.

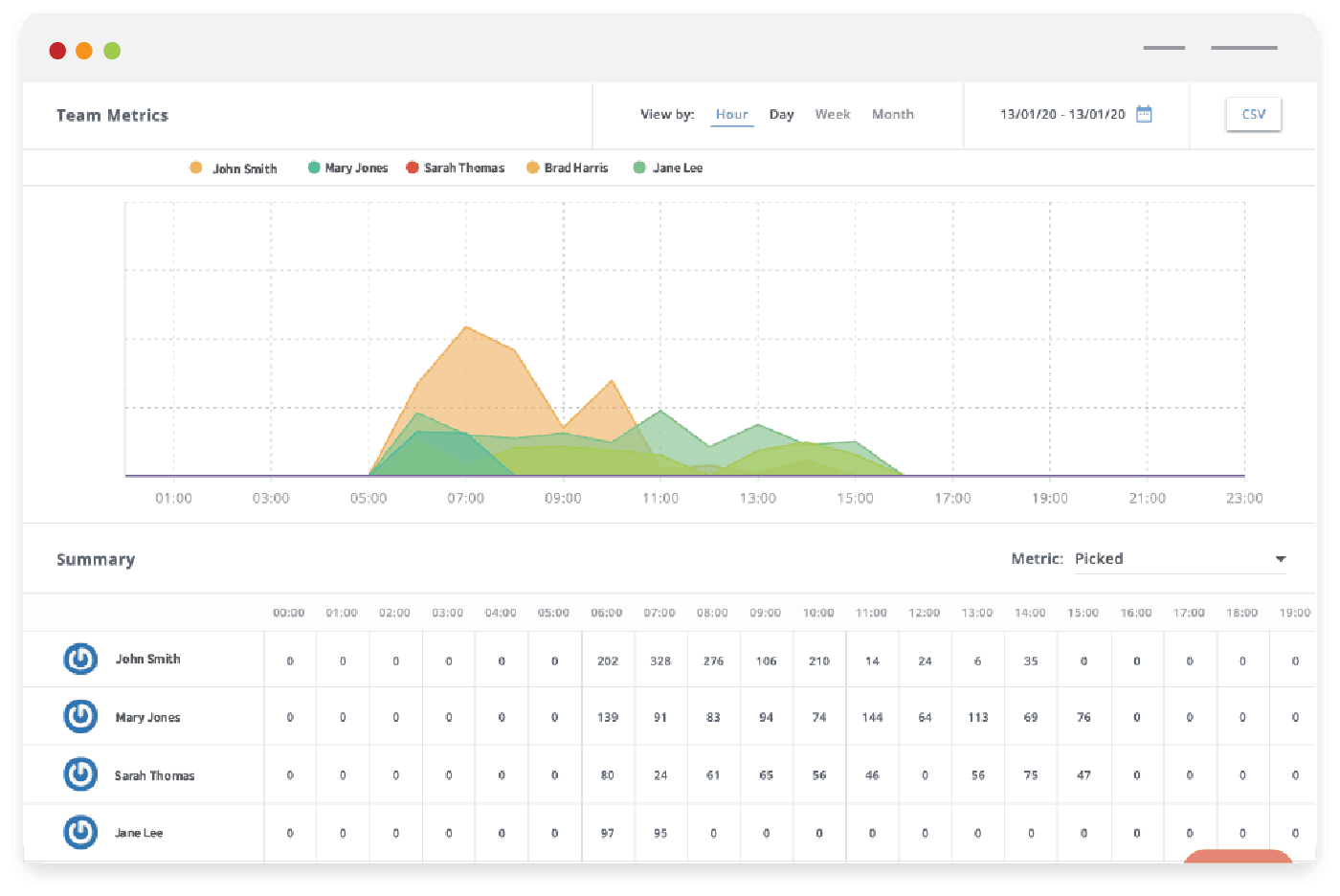

Easy to access and understand reports

It is important a MICS has a quality report system as this enables data-driven decisions about future purchases and sales of stock. A good inventory management system should be able to produce profitability reports, net sales reports, turnover reports and demand forecasting.

Ease to find audit trail

A modern inventory control system will give you an easy-to-access audit trail. So you will be able to see how inventory has been changed and updated, who has updated it, and when they did so. This is a big help when it comes to managing your warehouse effectively.

Helps create kits and bundles

A modern inventory system should be able to easily create kits and bundles. Kits and bundles are a great way to move stock, offer discounts or offer promotions. And a modern inventory control system will make it much easier for you to take advantage of this sales strategy by making it simpler for your team to fulfill these orders. Without an inventory management system capable of handling kits and bundles they can be an inventory tracking nightmare.

Allows for periodic inventory counts

Periodic inventory counts take less time than completely stopping operations to take a complete inventory count, are more flexible and more accurate. We’ve got a separate guide where you can learn more about periodic inventory counts here.

What are the advantages of a modern inventory control system?

If you are still considering whether a modern inventory control system is worth it, here is a list of benefits that a modernized system can offer.

Visibility for owners and operators

A modern inventory control system will shine a light into every aspect of their fulfillment operations. They should know where everything is at any point and be able to back through their reports and records to easily see where their workflows can be optimised.

Helps grow your business

A modern inventory control system can help boost your business through its modernized, efficient, and less time-consuming processing of managing your inventory as opposed to the manual updating spreadsheets. As a result, your business can utilize the time saved to focus on other factors that may contribute to its growth.

On top of this, the data you will receive on your inventory will help you make more informed decisions about your business.

Learn more about inventory management for small businesses.

Integrates with ecommerce tools and shipping carriers

To succeed in multi or omnichannel marketing you will need to be able to connect your sales channels, inventory management, warehouse management and shipping carriers together. They should also be an open API for any tools non-nativly integrated. This is a key part of Veeqo’s product.

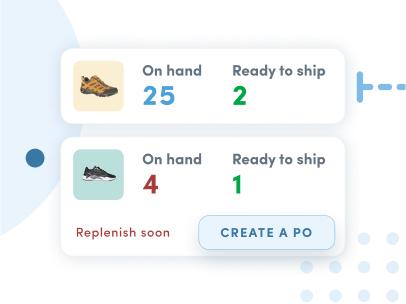

Reduces overselling and overstocking

This is a major advantage to having complete control and visibility over your stock levels. On one hand, you can make sure you have enough stock on hand to avoid overselling. While on the other you will be able to easily identify products that are taking up too much shelf space and aren’t being sold quickly enough.

Reduces returns due to mispicks

This is also very beneficial to the customer service aspect of your business, ensuring customers are satisfied in the first instance and reducing room for complaints.

How a inventory control system improves warehouse management

Modern inventory control systems should integrate fully with your warehouse operations. Simplifying fulfillment teams’ lives by automating a lot of the decisions they would otherwise have to make. This also has the benefits of making it less likely you will need to hire new warehouse staff and easier to train them when you do.

It should also be possible to optimize workflows and picking routes. Reducing how long it takes to fulfill individual orders.

Three useful formulas to help you get control of your inventory

If you are managing inventory yourself, it may be useful to understand these key formulas to help control your stock. They are simple enough to use and put into whatever spreadsheets you are using.

Economic Order Quantity (EOQ)

The formula is the square root of [2 (setup costs) (demand rate)] divided by holding costs. This formula is ideal for businesses that wish to minimize their inventory costs (for example, order costs, shortage costs, and holding costs). With the assumption that demand, ordering and holding costs remain constant, this formula is very cost-effective.

Reorder Point Formula

For this formula, multiply the average daily usage rate for an inventory item by the lead time in days to replenish it. The reorder point prevents your business from falling behind in the next supply of inventory as an accurate reorder point ensures there is enough inventory on hand to satisfy customer demand.

Inventory Turnover Formula

The formula for inventory turnover is the cost of goods sold (COGS) divided by the average inventory for the same period.

This formula helps your company understand the rate at which a business sells and replaces its inventory of goods during a certain period.

Inventory Turnover Calculator

However, whilst these formulas are useful to know, software like Veeqo can implement these formulas for you.

Inventory replenishment methods

There are some useful practices in place to help you replenish your stock, yet the methods differ depending on the type of industry your business is in.

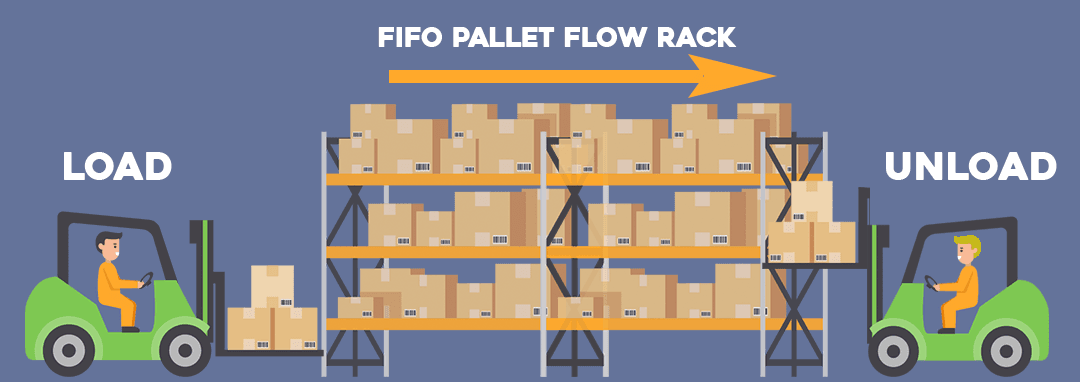

FIFO

FIFO is an abbreviation for ‘first in, first out’ and is often a method used in the hospitality industry. It indicates that you should aim to sell the items that first arrive in-store; therefore, older items will be placed at the front of the shelf whilst newer products are in the back. This avoids any potential issues with dead stock that may harm your business due to loss of profit. Secondly, it reduces the effect of inflation as oldest items are sold first.

LIFO

LIFO is the reversal of above and is an abbreviation for ‘last in, first out’. This method ensures most recently ordered products are sold first as they take priority over old stock. There are some advantages of this method, especially if the costs of manufacturing a certain product are on the increase. If you then sell the cheaper ones first, the cost of production is underestimated whilst your profits are overestimated. Therefore, LIFO can sometimes be a more reliable method that also sheds light on your earnings.

JIT (just-in-time)

The JIT method is used to control inventory for businesses that do not store raw materials. Instead, there are regular deliveries that only supply to companies what is required before existing raw materials are used up. However, this is only an effective method for businesses that have a good relationship with (ideally local) suppliers as this reduces lead time and delivery charges.

Two or three-bin system

The two-bin system operates to decide when products or production materials should be replenished. The first bin stores items that have been expended, orders are then made to refill or replace these items. As for the second bin, this is supposed to contain enough items to last until the order arrives for the first bin.

In the three bin, system, the third bin of inventory is saved for the supplier. Basically, a manufacturing warehouse retains a stock of inventory in two bins whilst the supplier of the inventory reserves one bin at his location. This method is mainly used to secure the flow of inventories during the production of the finished products.

Fixed Order Quantity

This method ensures the maximum and minimum levels of inventory are fixed. The maximum and fixed amount of inventory can be restocked once the inventory level reaches the auto set reorder level or the minimum stock level.

The fixed order allows for orders to be placed when economically feasible to do so. Furthermore, it requires little human involvement, it monitors inventory levels, and generates future orders automatically. The main issue that sometimes occurs with this practice is it may lead to some overstocking of certain products compared to others.

Fixed Period Ordering

On a periodic basis, orders are made to replenish the inventory. This can also be referred to as a fixed period deficit ordering system because every time the order is placed, the quantity of the products are different. This can be helpful in several ways. It helps the management of the inventory as you can check your current products against a pre-set reorder level, whilst taking into consideration any seasonal variations that may affect the choice in products.

Selling methods that can help control inventory levels

There are multiple methods to control the way your business sells its inventory. Here are just a few different ways that may help you to utilize your time more efficiently:

Kits and Bundles

The use of kits and bundles are an extremely efficient way to sell multiple products; however, this can sometimes cause issues for the warehouse team if not properly controlled.

Veeqo allows for an easy setup for your bundles because, as soon as a bundle is ordered, Veeqo makes sure your warehouse team knows exactly what to pick. By using Veeqo, not only is it time-efficient for all employees, with the software doing most of the work when selecting products for bundles, but it maximizes customer satisfaction by reducing human error.

Rolling Inventory

Rolling inventory is another helpful, time-efficient strategy that reduces the amount of effort spent on handling inventory for a business whose inventory is delivered to a warehousing area rather than being unloaded directly into the warehouse.

Instead, the delivery trucks that carry the inventory leave their trailers behind in the parking lot; therefore, when the inventory is needed at a retail store, a truck can pick up the trailer and take it there. This has been proven to be very cost-effective with some studies demonstrating a 9% save in costs associated with inventory management.

It is extremely helpful as it prevents stockpiling of certain products in the warehouse whilst reducing labor hours for the warehouse workers that track the inventory. Instead, shipments are produced, and dispatched, to meet customer demand.

Backordering

Backordering is when you let customers make orders even if you don’t have the inventory on hand. When they order from you, you immediately order from your supplier. It’s used to deal with a sudden surge in sales that leaves your business understocked.

However, backordering does sometimes cause dissatisfaction to customers due to the long waiting time of delivery.

Best practices for inventory control

Considering all of the different practices we have discussed throughout this blog, here are the best methods to employ in order to manage and control your business’s inventory to the best of your ability.

Frequent inventory audits

It’s vital to have an accurate count of your inventory at all times. If you do not use software capable of periodic inventory counting, then you may have to regularly shut down operations to do inventory counts, or risk overselling.

Choosing the right inventory costing method (FIFO or LIFO):

As discussed earlier, the inventory costing method will differ depending on the type of business you own or manage. Hospitality venues will be better suited to FIFO whilst the use of LIFO is helpful when the costs of manufacturing consistently fluctuate as LIFO ensures you can maximize your profits. Make sure to evaluate the different inventory costing methods for your business before deciding on one as this is an important aspect that can save you money and time if selected correctly.

Establish safety stock levels

Ensure that you have extra quantities of items for popular products to prevent an out-of-stock scenario. It is important to implement safety stock as not only does it prevent the hassle or panic of running out of stock, but it also covers you until the next stock arrival.

Make data-based decisions on inventory levels

Data and analytics are crucial tools to control your inventory. To have good control over your inventory, you need to be regularly accessing relevant reports that contain inventory count, sales data, and sell-through rates.

Veeqo helps with this due to its smart inventory forecasting feature which allows retailers to manage their inventory quickly and with minimal effort. It ensures accurate predictions of future stock, reduces the likelihood of stock-outs, whilst also being extremely cost-effective by preventing you from maintaining an excess of stock.

Hopefully, this article has shed some light on how to help your business manage its inventory effectively. Whilst there are multiple methods that you can use, investing in an advanced software tool like Veeqo will greatly benefit your ecommerce business, ensuring that you can save time and money that may be better used elsewhere.

About the author

This article was written by Michelle Lau, Head of Product at Veeqo. Michelle leads a team of product managers to make sure Veeqo is the best order fulfilment tool for ecommerce retailers.