Ecommerce

Why Global Unrest Drives Local Supply Chain

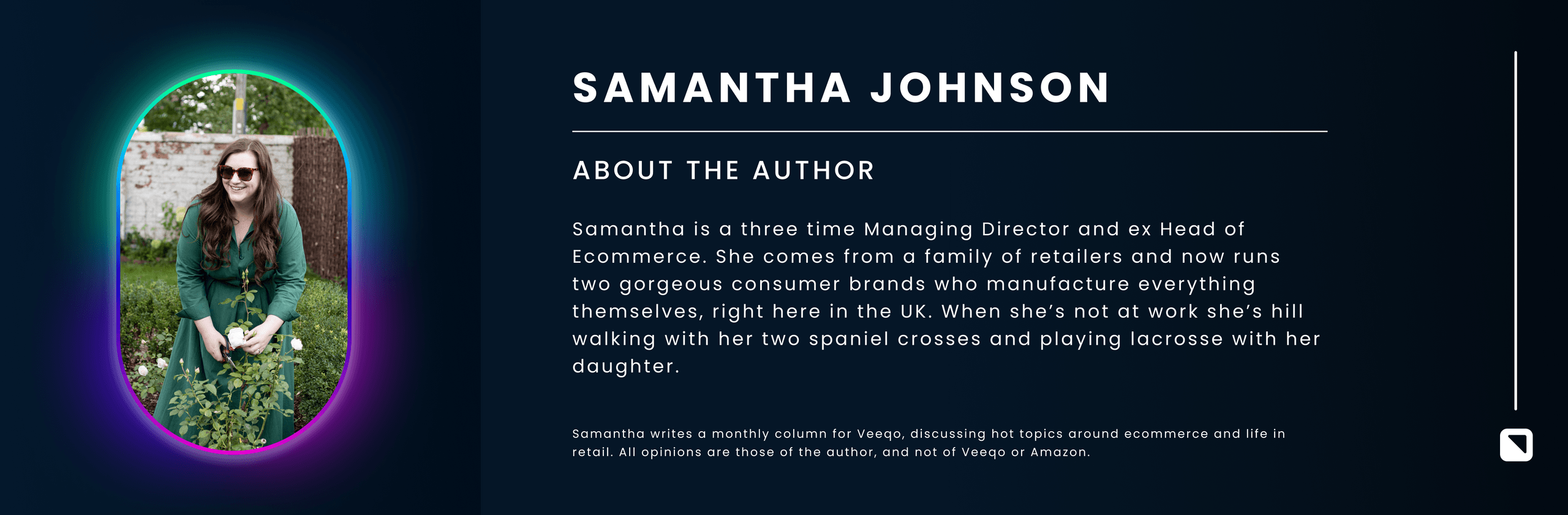

- Written by Samantha Johnson

If you’ve become someone who is very cautious about the news you engage with, I don’t blame you. Our Production Director, my husband, is ex Commander Royal Navy and recently completed a long stint working at NATO. So our household is pretty familiar with the impact of international conflict on domestic UK lives.

Our combined experience of current affairs and home grown commerce is probably why we ended up deciding to spend our lives building UK manufacturing capability.

I’ve spent decades working in High Street retail and scaling consumer start-ups…mainly wasting time rewriting business and product plans because of stock gone awry.

The global supply chain challenges of the last five years would almost be funny, if we weren’t stuck not learning the lessons of the past.

From containers of PPE blocking Felixstowe to Suez being closed before Christmas, oil prices soaring and now we see shipping companies avoiding the Red Sea due to further security threats.

When these events happen, the costs of moving containers globally spirals. And it’s a real driver of global inflation - if retailers are charged through the nose to bring in goods, they are going to put prices up. Our high street retailers are targeted on shareholder return and they’re not about to take margin hits in Q1, which is tight enough as it is.

The thing about big retail, is that change is expensive and time consuming.

Head Office buying teams are small, time poor and finding UK supply is sometimes really difficult. But for those of us who don’t spend our days writing corporate reports, there is huge opportunity for speed and agility to get ahead of these industry stalwarts by sourcing locally.

When we designed our business, we wanted to make homeware that was totally designed to help independent brands get ahead and take on high street giants. By meeting the challenges of:

Speed to market

Minimum Order Quantity

Personalisation

So, we built a manufacturing house that (a) was design-led, filled with creatives and product people with a great eye and (b) uses all the possible tech available to combine small production runs for maximum efficiency.

This allows us to make small quantities of bespoke designs for independent retailers across the UK and internationally. We can design, manufacture and supply new lines to market in weeks - not months. With a fair wind behind us, we can do it in days.

We lean into small production runs, gathering data, scaling up - and then knocking the results out of the park.

And, whilst those best sellers do their thing, we get back to searching for the next big thing and continue to test ideas all the time.

As we run consumer brands, as well as manufacturing private label, we have the full range of data sources to draw from to ensure we stay lean and fast.

The speed of media consumption, and the rise of new trends is not slowing down. Global unrest isn’t slowing down either. So, frankly, being stuck in these 12-18 month product development cycles is madness.

It’s commercially limiting, environmentally damaging and a huge drain on time and creative energy.

So, whilst made in the UK has a perception of being heritage and expensive, I challenge you to look at the true cost of far eastern imports and consider testing UK production skills to see what it could do for you.

Editor's note: Like all of our freelancer contributors, Samantha is compensated for her work. We work hard here at Veeqo to ensure that the majority of our writing team have real-life experience in ecommerce and retail, in order to bring the highest writing standards and advice to our readers.